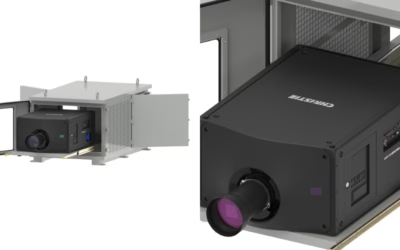

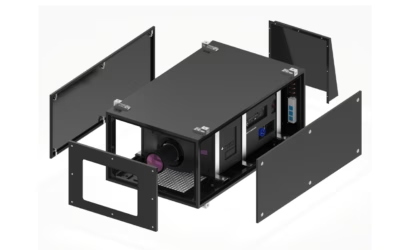

Compact High-Luminosity Forced-Air Cooling Projector Enclosure (8000-15,000lm) with Custom Color Service

1. Specifications & Performance

Luminosity Range: 8000 to 15,000 ANSI Lumens, suitable for medium to large venues, bright ambient light environments, and outdoor use.

Cooling System: Advanced forced-air cooling system with a multi-channel, low-noise design.

Dual/Triple High-Efficiency Fans: Strategically placed for intake and exhaust, creating a directional airflow path over the critical heat zones (lamp/LED module, DLP/LCD chip, power supply).

Independent Air Ducts: Isolates airflow for the optical engine and electronics to prevent heat crossover and ensure efficient thermal management.

Intelligent Speed Control: Fan speeds adjust dynamically based on internal temperature sensors, balancing cooling performance with acoustics. Operates quietly at lower loads.

Enclosure Design:

Material: High-grade aluminum alloy chassis with integrated heat-dissipating fins and precision-molded polymer components. Optimized for structural rigidity, EMI shielding, and maximum heat transfer.

Compact Form Factor: Engineered for a minimal footprint despite high power, facilitating easier installation and transport.

Sealed Optics Path: Protects the optical core from dust ingress, maintaining long-term image clarity.

2. Key Features & Benefits

Enhanced Reliability & Longevity: Superior thermal management directly extends the lifespan of the light source (laser phosphor, LED, or high-pressure lamp) and critical projection components, reducing long-term maintenance costs.

Sustained Peak Performance: Prevents thermal throttling, ensuring the projector maintains its rated brightness and color accuracy even during extended operation.

Installation Flexibility: The compact size and efficient cooling allow for installation in tighter spaces or enclosed cabinets with proper ventilation considerations.

Reduced Maintenance: Effective dust filtration and a sealed light path minimize the frequency of internal cleaning.

3. Custom Color Service

Full Enclosure Customization: The entire outer shell—including top, sides, front, and rear panels—can be finished in a color of your choice.

Premium Finishes Available:

Powder Coating: Durable, scratch-resistant, and uniform finish in any Pantone, RAL, or custom-matched color. Offers matte, semi-gloss, or gloss textures.

Anodized (for metal parts): Hard-wearing, corrosion-resistant metallic finish available in standard colors (black, silver, gold) or limited custom hues.

Vinyl Wrapping: For complex graphics, branding, or specific textures without the cost of custom paint. Easier to update or change.

Process: Client provides color sample or code → Manufacturer matches and provides approval samples → Full production run.

Typical Applications: Corporate branding (matching company colors), architectural integration (blending with venue decor), special events (themed installations), premium product line differentiation.

4. Use Cases

Digital Signage & Retail: High-brightness displays in shopping malls, store windows.

Museums & Galleries: Projection mapping on exhibits where precise color and compact size are needed.

Boardrooms & Auditoriums: Professional installations requiring discrete, powerful projection.

House of Worship & Lecture Halls: Long operational hours in fixed installations.

Rental & Staging: Durable, reliable, and visually customizable for events and tours.

Simulation & Control Rooms: Where consistent performance is critical.

5. Technical Considerations for Integration

Ventilation Requirements: Despite forced cooling, ensure the installation environment provides adequate clearance (as per spec sheet, typically >50cm around intakes/exhausts) and ambient airflow.

Acoustic Noise: Verify dB(A) ratings for noise-sensitive environments like lecture halls or small studios.

Service Access: Design the installation to allow for periodic filter cleaning or maintenance, even with a custom-colored enclosure.

Lead Time: Custom color finishes will add to the manufacturing and delivery timeline.

6. Photos On-Site

LEAVE A COMMENT