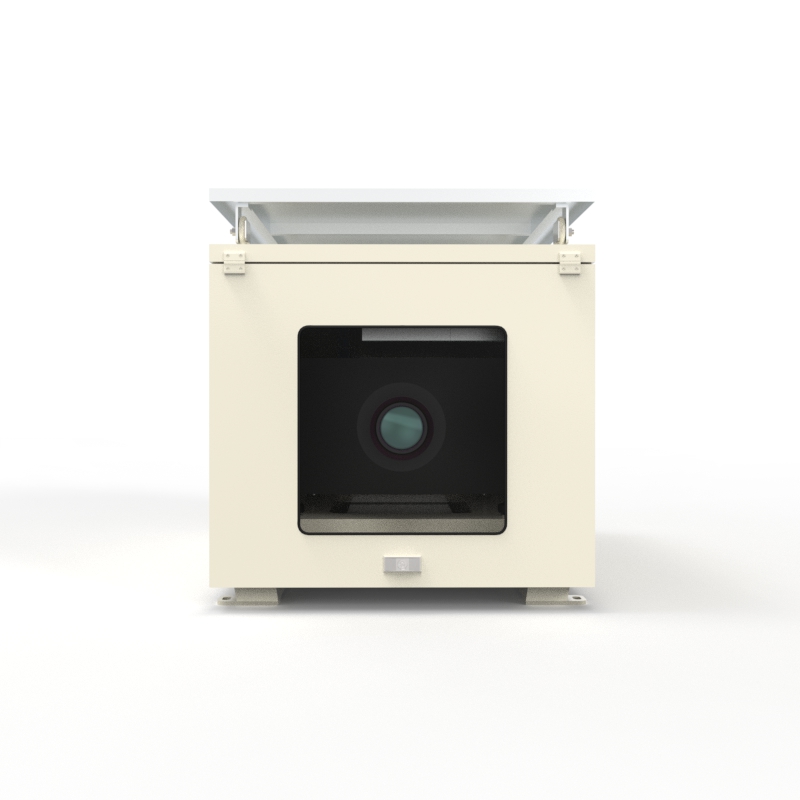

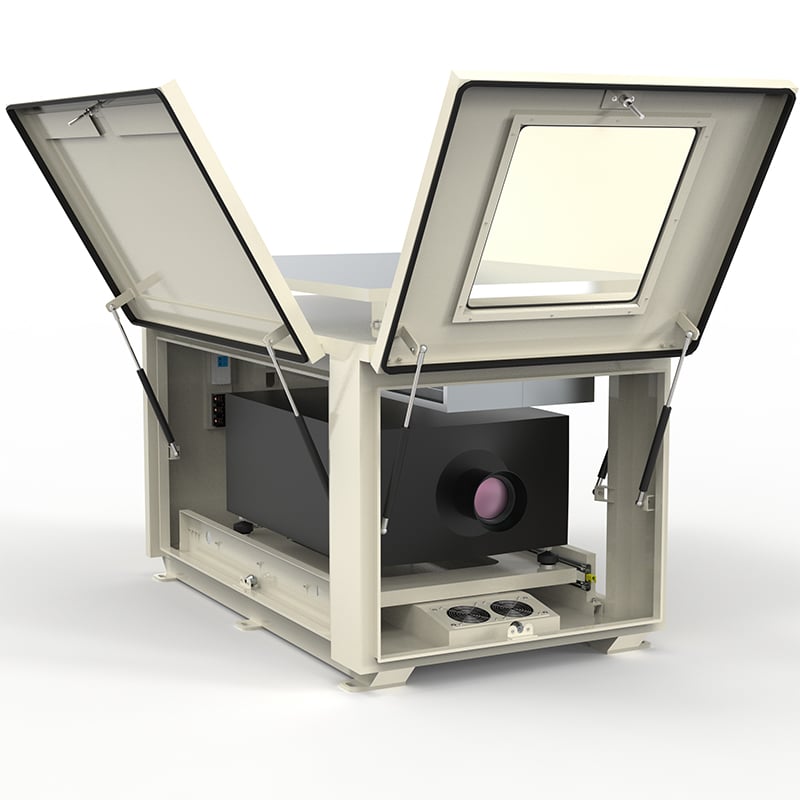

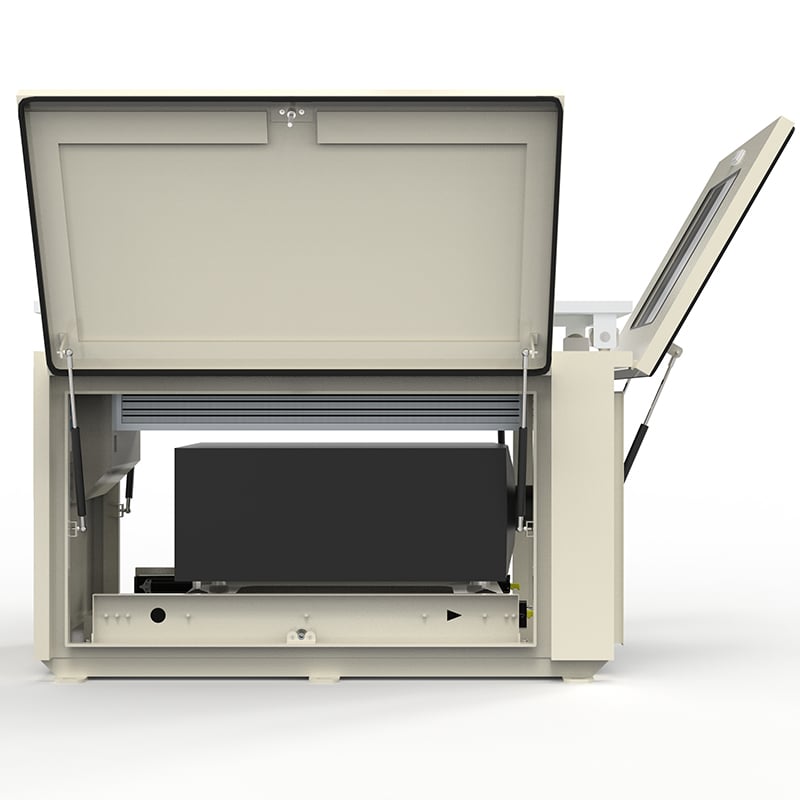

Christie Griffyn 4K50-RGB Split-Type Projector Enclosure with Independent AC Unit

PROFESSIONAL-GRADE THERMAL MANAGEMENT FOR CHRISTIE GRIFFYN 4K50-RGB LASER PERFORMACE

Engineered exclusively for the Christie Griffyn 4K50-RGB laser projector, this split-type enclosure system revolutionizes outdoor and harsh-environment projection protection. By separating the climate control unit from the projector enclosure, it delivers superior cooling efficiency, whisper-quiet operation, and uncompromised reliability—ensuring your high-brightness RGB laser projector maintains studio-quality performance in the most demanding permanent installations.

SPLIT-TYPE SYSTEM ARCHITECTURE

Dual-Component Design Philosophy

Projector Enclosure Module: IP65-rated sealed chamber containing only the Griffyn 4K50-RGB projector

Independent AC Unit: Remote-mounted precision air conditioning system with redundant components

Refrigerant Line Connection: Factory-charged, insulated copper lines (typically 3-10 meter options)

Electrical Separation: Independent power circuits for projector and climate systems

Key System Advantages

Thermal Efficiency: 30-40% more efficient than integrated AC designs

Acoustic Optimization: Moves noisy compressor components away from projection site

Service Accessibility: AC unit mounts at ground level for easy maintenance

Heat Rejection Management: Exhausts hot air away from optical path and intake areas

Space Optimization: Slimmer projector enclosure fits in tighter spaces

PROJECTOR ENCLOSURE MODULE

IP65 Sealed Chamber Design

Monocoque Aluminum Construction: 2mm seamless welded chassis with reinforced mounting points

Hermetic Optical Assembly: Multi-pane heated glass with anti-reflective coating and UV protection

Positive Pressure Maintenance: Continuous slight positive pressure prevents dust infiltration

Vibration-Isolated Mounting: Christie-engineered isolation platform with 6-axis damping

Enclosure Specifications

Dimensions: 120% of projector volume for optimal airflow

Window Material: 12mm laminated optical glass with heating elements

Cable Access: Sealed bulkhead connectors with drip loops and strain relief

Internal Finish: Matte black anti-reflective coating

INDEPENDENT AC UNIT

Precision Climate Control System

Dual-Circuit Design: Independent cooling circuits with automatic load balancing

Capacity: 18000 BTU/hr (3.5 kW) cooling capacity

Dehumidification: Active moisture removal maintains 40-50% RH

Technical Specifications

Compressor Type: Inverter-driven scroll compressor for variable capacity

Refrigerant: R410A or R32 (environmentally preferred)

Power: 208-240V AC, 20A dedicated circuit

Noise Level: 52 dBA @ 1m (outdoor unit)

Dimensions: 900H × 800W × 350D mm

- Mounting: Wall bracket or ground pad options

INTELLIGENT CLIMATE MANAGEMENT

Dual-Zone Temperature Control

Laser Engine Zone: Maintains 22°C ±1°C for optimal RGB laser performance

Electronics Zone: Maintains 25°C ±2°C for processing and power components

Optical Path Zone: Stable temperature prevents focus shift and color drift

Smart Operational Features

Predictive Cooling: Anticipates thermal loads based on content brightness and ambient conditions

Weather Integration: Adjusts operation based on local forecast data

Economy Mode: Reduces power consumption during projector standby

Defrost Cycle: Automatic for cold climate operation

Monitoring & Alerts

7-Point Temperature Sensing: Continuous monitoring throughout enclosure

Humidity & Dew Point: Active condensation prevention

Refrigerant Monitoring: Pressure and flow sensors for system health

Remote Diagnostics: Christie Connect integration for proactive maintenance

INSTALLATION & INTEGRATION

Professional Installation Requirements

- Site Assessment → 2. Mounting Bracket Installation → 3. Refrigerant Line Routing → 4. Electrical Connection → 5. Vacuum & Charge → 6. System Commissioning → 7. Performance Testing → 8. Remote Monitoring Setup

Refrigerant Line Specifications

Line Set: Insulated copper, factory pre-charged

Maximum Length: 30 meters (with elevation correction)

Minimum Length: 3 meters for proper compressor operation

Connections: Quick-connect fittings with leak detection

Electrical Requirements

Projector Circuit: 200-240V AC, 30A

AC Unit Circuit: 208-240V AC, 20A (dedicated)

Control Wiring: Low-voltage communication lines included

- Surge Protection: Integrated on both circuits

SPECIALIZED ENVIRONMENT PACKAGES

Coastal/Marine Edition

Materials: 316L stainless steel fasteners, salt-resistant coatings

Corrosion Protection: Cathodic protection, enhanced drainage

AC Unit: Tropicalized with anti-corrosion treatment

Extreme Cold Edition

Heating Upgrade: 4.0 kW heating capacity

Cold Start Kit: Compressor crankcase heater

Line Set: Extra insulation and trace heating

High Altitude Edition

Compressor: High-altitude optimized

Pressure Adjustments: Refrigerant charge optimized for elevation

Cooling Derating: Calculated based on installation height

Industrial Edition

Filtration: Enhanced particulate and chemical filtration

Construction: Heavy-duty materials, explosion-proof options

Monitoring: Enhanced sensor package for air quality

MAINTENANCE & SERVICE

Routine Maintenance Schedule

Monthly: Filter inspection, visual system check

Quarterly: Coil cleaning, refrigerant pressure check

Annual: Comprehensive system inspection, component testing

Biannual: Professional service recommended

Service Advantages

Ground-Level Access: AC unit mounted for easy technician access

Modular Components: Quick replacement of individual system parts

Remote Diagnostics: 85% of issues diagnosed without site visit

Parts Availability: Common components stocked globally

Predictive Maintenance Features

Compressor Health Monitoring: Vibration and temperature analysis

Refrigerant Tracking: Automatic leak detection and charge monitoring

Component Life Prediction: AI analysis of operational data

Automated Service Scheduling: Integrates with Christie service network

APPLICATIONS & BENEFITS

Ideal Installation Scenarios

Architectural Projection: Building façades, monuments, structures

Entertainment Venues: Theme parks, outdoor theaters, stadiums

Corporate & Institutional: Headquarters, campuses, museums

Special Events: Permanent installations for recurring events

Business Advantages

Energy Efficiency: 30-40% lower operating costs than integrated units

Reduced Noise: Critical for noise-sensitive venues

Extended Lifespan: 8-10 year typical service life

Higher Reliability: Separate systems prevent cascade failures

Better Performance: Stable temperature improves color accuracy

THE PROFESSIONAL’S CHOICE

The Christie Griffyn 4K50-RGB Split-Type Projector Enclosure with Independent AC Unit represents the professional standard for high-performance outdoor projection protection. It delivers:

“Studio-quality thermal management with field-proven reliability—ensuring your RGB laser investment performs flawlessly, year after year, regardless of environmental challenges.”

This system is designed for integrators and end-users who demand the highest level of performance, reliability, and serviceability. By separating the climate control from the projector enclosure, it achieves what integrated systems cannot: optimal cooling efficiency, minimal acoustic impact, and simplified maintenance—all while maintaining the precise environmental conditions required for exceptional RGB laser performance.

Product Details

Panorama (click and drag the cursor to turn around the view)

LEAVE A COMMENT