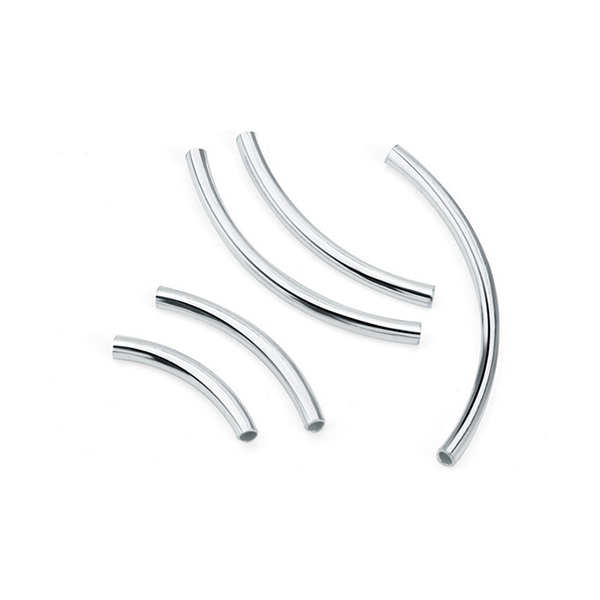

Pipe Bending Forming And Fabrication Service

China 518107, Guangdong / 广东, Shenzhen, XinWei Third Industrial Zone, Xinhu street

Company Profile

We are a factory engaged in pipe products processing, wire products processing, hardware accessories customization, protective mesh cover production, we have many years of pipe products related product design, production, sales and service experience. With strong technology, stable quality, integrity management, and the spirit of continuous innovation to promote the development of the company. At the same time, we continues to summarize experience and optimize the service, and win the new and old customers highly evaluation and recognition.

Essential

Place of Origin: Shenzhen, China Brand Name: Chongdao Industrials

Business type: Trading Company Total employees: 80 – 150 People

Main Products : Stamping Part, Auto Part, CNC machining parts, Deep drawing parts, Steel febricating parts

Model Number: customized Material: aluminum, mild steel, stainless steel

Finish: zinc plate, powder coat and etc. Size: customer’s Drawings

Certificate: ISO9001: 2015 Service: custom metal tube bending forming

Service capability: one stop solution

Supply Ability

Supply Ability: 100000 Unit/Units per Month

Packaging & delivery

Packaging Details: carton, pallet, wooden case or as per customers’ package requirements

Port: Shenzhen/Yantian or Shekou

Main Business

Custom tube pipe bending forming service, custom metal tubular products fabrication service.

Bending products, shrink pipe, drilling, welding, stamping, balance car support, medical basket, light crafts, iron wire crafts, bending pipe crafts, square iron crafts, Flat iron crafts, cloth table lamp, wall lamp, chandelier, lighting tube, furniture bend pipe, lighting main body, lighting bracket, lamp explosion-proof net cover, bathroom shelf, storage basket, baseball protective cover, kitchen dish rack, iron wire candle holder, iron wire wine rack, iron picture frame. The products on the website are only part of the products, we can offer more pipe products, wire products and other hardware products.

- Cooperation model: OEM or ODM

- Design: As per customer specific requirements

or customer give us the specified sample;

or the customer conceptual or preliminary design;

or the customer sketched idea. - Accept drawing format: .jpg / .dwg / .igs / .stp / .prt / .3ds / .skp etc..

- Material: Sheet stock is of many materials, including carbon steel, alloy steel, stainless steel, aluminum, brass even plastics.

- Material condition: On flat sheet, plate coil supplying condition, Hot rolled or cold rolled or cold drawn for options.

- Material thickness: From 0.2mm~6mm

- Application material standard:

If there is no any specially requirement, we often sugguest our customer to try the equivalent China National (GB) standard material that our engineering team proposes which to be properly converted from ANSI, ASTM, SAE, EN, DIN, BS, JIS, and etc., to contribute the material cost control.

If it is necessary to use exact designated material no., it is also possible choice. Available processing (Technique):

– Shearing – Crimping – Laser cutting – Bending – Stamping – Pressing- Deep drawing – Rolling – Forming – Fabricating – Drilling- Tapping – Riveting – Spot welding – TIG – Assembling- Precision: Average level: ±0.05mm, depending the part size and thickness and material

- Tooling in house: To design and build the necessary tooling in own house, for the tooling we never add any margins, it just cost.

- Heat treatment (out house): For the heat treatment, we subcontract to our local qualified supplying factories to process at the out of Chongtao house. Generally we can meet any heat treatment requirements on the metal works, such as annealing, normalizing, tempering & quenching, surface hardening and etc.

- Surface treatment: The surface treatment is to do out house. Our suppliers help us to supply our customers a wide range of surface finish solution, such as hot dip galvanizing, zinc plating, nickel plating, chrome plating, powder coating, epoxy painting, anodizing, black oxide, E-coating and etc.

- Inspection:

Whole inspection procedures (IQC, PQC and FQC) and QA plan are carried out in house to be compliance with the rules and regulation of ISO 9001:2000

Quality control always be doing on site and on time, never try to do later;

If the customer found it is necessary any third authorized inspection organization are welcomed to witness the quality before the shipment. - Packing:

Strictly in accordance with the customer specific instruction on the packing

We can package for retail if needed

If no any specified, generally we would recommend that the parts to be packaged by a poly bags, then put them in cartons, and finally to be on the pallets. The gross weight of one carton is not more than 22kg and pallet size try to approaching 120cm×80cm (Europe size) and 42″×42″ (US size)

The package is seaworthy and suitable for export. The woodern package material shall be steamed with the certificated and stamped by CCIB - Applicable field: All kinds of auto parts, machinery parts, computer parts, medical parts, home appliances, electrical equipment parts, electrical appliance parts, electronic products parts, electronic parts, generator parts, alternator parts, dynamo parts, electric generator parts, stationery, power switches, miniature swithces, architecture, commodity and A/V equipment, hardware and plastic molds, sports equipment and gifts, etc.

- Reminding:

The metal parts showed on the chlook.store are not for sale, it just for sales promotion purpose it is to explain for our potential customers that we had produced or are capable of making such similar metal parts or supply same metal processing services.

For any custom metal parts before mass production, we need our customer to confirm and approve the working samples. For more information on the sample issue, please visit our “Sample Procedures and Sample Policy” to get more details.

Our engineers are in mechanical field for over 10 years. We can give you the most professional solutions on your designs.

Contact us at any time, we will give you the best quotes in one or two working days.

Our Plant

Main equipment: straightening and cutting machine, pedal-type spot welder, edging machine, winding machine, pipe bending machine, punch, pipe cutting machine, head machine, tooth rolling machine, polishing machine, argon welding machine, CO2 protection welding machine, butt welding machine, tapping and tooth rolling machine, drilling machine, etc.

Main process: straightening and blanking, bending, ring, drilling, welding, stamping, grinding and polishing, anti-corrosion treatment, etc.

Production and processing methods: processing, sample processing, OEM processing, etc.

Located in Shenzhen China.

Would like to know more about us?

If you have any questions about our product and service, please do not hesitate to contact us immediately, we will reply you as soon as possible.

Contact Us

Address

1 / F, Building A3, Chenwenli Industrial Park,

Guangming District, Shenzhen, China

yzjfactory@gmail.com

Tel: +(86) 0755-2324-6723

Whatsapp: +(86)075523246723

Wechat: 19875508919